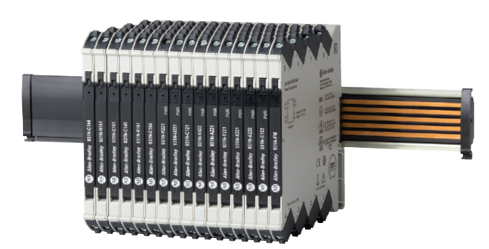

Allen-Bradley® 931N ‘Nano’ Signal Conditioners provide optimal signal isolation, conversion and amplification. The range includes both isolation and conversion model options and includes a powered DIN-rail feature, which eliminates the need to separately wire devices to the power supply. The 6mm width also allows you to save space in the panel!

Critical process measurements such as temperature, pressure, flow, level, weight, speed, frequency, current or voltage in your continuous or batch production process are exposed to noise and harsh environmental conditions that result in erroneous signals. In this respect, 931N signal conditioners can help protect your measurements and provide a more reliable signal so your process can run efficiently.

These DIN rail-mounted analogue signal conditioners are compatible with all types of integrated PLC and DCS I/O systems. They can also be integrated with PlantPAx® DCS to leverage a single control platform for batch, drives, motion control, process and safety.

Signal conditioners are commonly used in industries such as food and beverage, pharmaceuticals, oil and gas, water treatment, energy and power, chemical processing and steel production.

Features and benefits include:

- Helps protect your expensive control system from transients and noise

- Thoughtful design with easy onboard configuration, 6mm space saving housing and angled terminals for ease of wiring

- Reduced overall wiring time via the use of a power rail option, which reduces supply wiring requirements. One feed module powers up to 75 devices!

- Eliminates ground loop/noise-induced errors in process measurements through high levels of galvanic isolation

- Cost effective signal conversion to solve a signal mismatch between field device and I/O

- Eliminates signal degradation of critical process measurement during transmission

- Converts thermocouple/RTD measurements economically

- Accurately reproduces the signal using latest transformer and optical technologies

- Reduces the need to run expensive cables to transfer signals to control system

- Enables dedicated local display through signal splitting

- Extensive certifications for global use including UL/CSA, CE, ATEX, IECEx, FM, DNV-GL, KC, RCM, Hazardous Area (Class 1 Div 2 / Zone 2)

For more information, please contact your local NHP Account Representative or email us:

Australia 1800 647 647 nhpsales@nhp.com.au

New Zealand 0800 647 647 sales@nhp-nz.com