Potential Risk

Many fast-paced modern businesses often fall into the trap of delaying the routine service of critical electrical switchgear, in order to avoid lengthy power shut downs. Unfortunately this can result in the deterioration and premature failure of switchgear contacts, conductors and connections. Consequentially, the switchboard and switchgear starts to overheat. This abnormal heating can lead to pre-mature failure of switchgear and also constitutes a potential fire hazard, leading to unexpected power and financial losses for the site.

There are many technologies available today which can help detect abnormal temperature conditions in a switchboard, however most of these have significant limitations. For example, in many power critical applications such as data centres, hospitals, utilities and mining sites use technology such as thermal imaging to help identify over heating in switchboards, but this method is only valid during that specific ‘snapshot’ in time.

Innovative protection

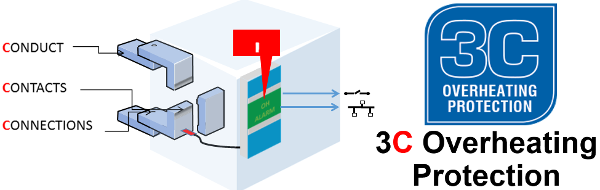

Modern ACBs use electronic trip unit for protection, which is mainly monitoring current and voltage. Knowing the critical effect of overheating, Terasaki’s innovation team adopted fully integrated temperature condition monitoring systems to continually check for overheating abnormalities that could be due to issues with the main contact, connections and conductors. Terasaki named this temperature monitoring methodology, calling it ‘3C’.

3C overheating protection detects the abnormal temperature within the contacts area, and activates the alarm in the trip unit. The ACB trip unit can be configured by the site engineer to ‘trip’ or just ‘Alarm’ (ie. No trip, just notification shown on the LCD screen and can be indicated via volt-free output contact or via the data communications network or both) if overheating occurs.

The 3C overheating alarm can help the facility manager develop predictive maintenance plans and minimise down time and secure power availability. Furthermore Terasaki have recently upgraded the 3C overheating protection system, now real time temperatures and be viewed via the LCD and the Modbus communications showing the current hottest contact temperature. This allows end users to extract the continual contact temperature for reporting and analysis purposes.

The implementation of condition monitoring techniques such as 3C can be equally applied to older installations as well as new ones. As sites consider retrofit solutions to replace ageing switchgear with new ones, they can also take advantage of that extra dimension for switchboard protection to reduce the risk of sudden failure to the site.

Further Information

Contact your local NHP specialist to discuss how a customised industrial automation and Terasaki TemPower 2 ACB solution with integrated 3C protection can be implemented on your site.