Introducing the Connected Enterprise

Accelerated by the emergence of the Internet of Things (IOT), the Industrial Internet of Things (IIOT) and the advances in enabling technologies, the Connected Enterprise elevates opportunity through greater connectivity and information sharing.

In essence, the concept of the Connected Enterprise consists of industrial operations that are intelligent, optimised, and secure. Central to achieving this is the convergence of Information Technology (IT) and Operations Technology (OT) into a single unified architecture. This architecture can then be used to capitalise on operational, business and transactional data for improved enterprise, operations and supply chain performance.

Further to achieving this vision, it is critical to have connectivity at every level; this includes any sensor, valve, motor starter, contactor, breaker or relay at a particular site.

Achieving a Connected Enterprise in existing plants

With much hype around the IOT and the IIOT, global automation companies are busily building Ethernet into their devices to allow enhanced communication and turn terms such as Industry 4.0 into a reality.

The Connected Enterprise brings top floor and plant floor together to optimise productivity and competitiveness, however, for existing plants a common challenge exists - how do we enable all this proposed value? Upgrading controllers with Ethernet and buying new OEM machines with current technology may not result in production increase and may even cause availability issues and security breaches if the backbone of the system, being the plant network, is not where it needs to be.

It's common in 2016 for a manufacturer’s network infrastructure to have grown organically over many years, with many switch types being added sporadically to meet the connection requirements. With an irregular upgrade process, even large multinational companies’ network infrastructure can vary; from flat networks where the corporate and factory networks co-exist, to independent networks with an air gap. Both ends of the spectrum present issues. On a flat network, a simple incorrect plug of a cable or a faulty router in the corporate space has the potential to stop the plant’s operations. Whereas, if an air gap exists then the potential for real time data analytics is impossible. In the middle of these exists the required structures to allow the Corporate or IT space and the Factory or OT world to work cohesively and converge together.

Although the concept of convergence between the IT and the OT infrastructures is not a new one, it still remains that the wants and needs of these two networks can be vastly different. There are however some critical commonalities: performance and security.

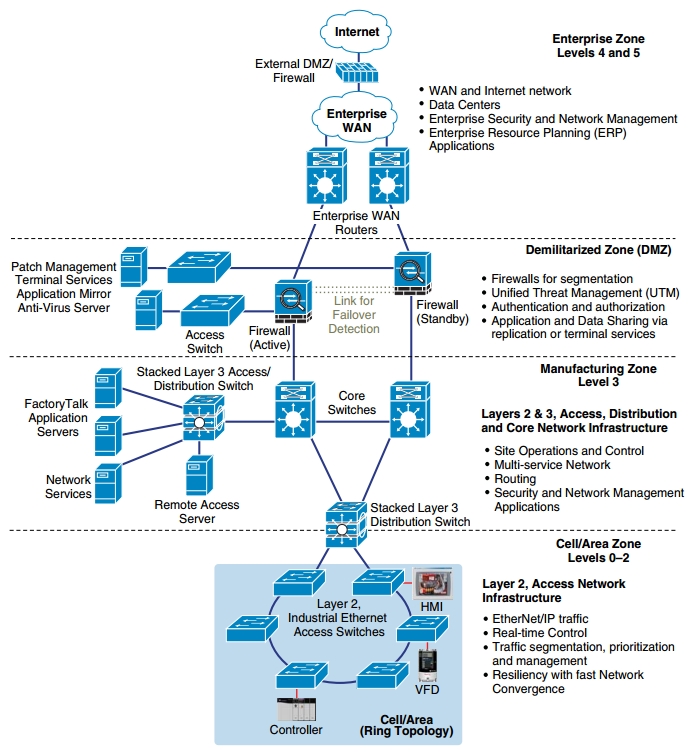

The below image from the Rockwell Automation's Converged Plant Wide Ethernet Guidebook shows some of the structures that can be implemented to provide the required performance, availability and security to enable the Industrial Internet of Things:

As you can see, variations to tradition al IT structures are used to achieve the OT requirements of today’s manufacturing, exposing the differing and common challenges and solutions compared to corporate infrastructures. Getting your infrastructure right paves the way for reaping the benefits of what will be ongoing developments in the ever connecting world, allowing IT and OT to effectively work together for the overall company’s betterment.

Partnering with NHP to achieve a Connected Enterprise

To fully experience these benefits it’s important to first partner with a company that understands and can enable your vision and at NHP we deliver automation, intelligent motor control and sensing solutions that promise future integration to enable your Connected Enterprise.

NHP has recently entered into a partnership with industry leaders, Rockwell Automation and CISCO, to bridge the gap between systems. This partnership allows NHP to deliver one solution from the enterprise to the Industrial Demilitarized Zone (IDMZ) and now down to the factory floor improving and scaling security monitoring and management.

NHP offers increased workforce efficiency and lower total costs of ownership enabling you to transform data into actionable and real-time information. Employing standardised and secure networks through smart manufacturing, NHP provides a wide range of devices ensuring connectivity, efficiency and equipment safety.