How to Meet OT Cybersecurity Standards

09/07/2025

As cybersecurity regulations tighten across the industrial sector, system integrators and OEMs are under increasing pressure to design automation systems that not only perform but also comply. With frameworks like IEC/ISA 62443 shaping procurement policies, tender requirements and insurance expectations, network security has now become a fundamental part of every project.

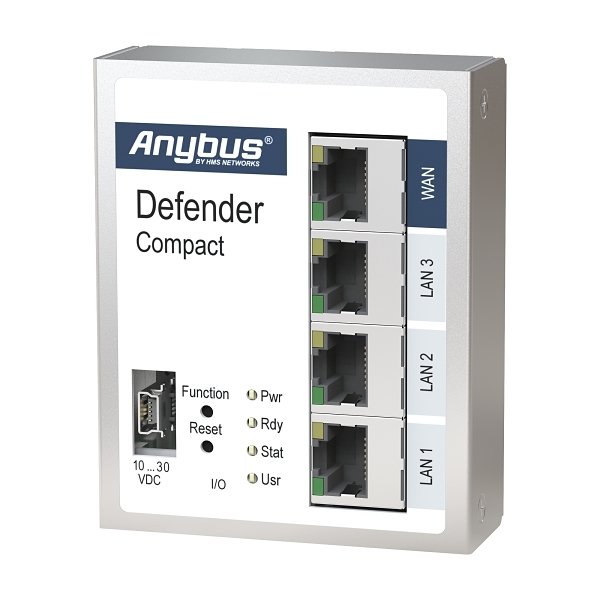

To help meet these evolving demands, NHP now offers the HMS Anybus Defender — a rugged, easy-to-deploy firewall built specifically for operational technology (OT) environments. It offers the kind of protection, segmentation and traffic control that aligns directly with regulatory standards, without adding unnecessary complexity to automation design.

IT systems manage data, communications, and enterprise software, while OT systems control machinery, sensors, and industrial processes. Whilst they traditionally operated in silos, today they're deeply linked. This integration, while transformative, also introduces new vulnerabilities. IT systems are typically well-defended with mature cybersecurity protocols. OT systems often rely on legacy infrastructure that prioritises uptime over security, making them a vulnerable point of exploitation—potentially disrupting production or damaging equipment.

Johan Barona Andrade, who leads automation at NHP, notes that industrial customers are no longer asking if cybersecurity is necessary — they’re asking how fast they can get compliant.

“We’re seeing real momentum behind standards like IEC 62443. Customers want to future-proof their systems and reduce risk, and system integrators need tools that help them do that without compromising uptime. That’s where the Anybus Defender comes in — it easily fits into old systems and immediately brings it up to standard.”

At its core, the standard emphasises segmentation — dividing systems into clearly defined zones and monitoring the traffic between them. The Anybus Defender supports this through both logical and physical segmentation, allowing integrators to separate more critical machines from less critical ones, and isolate control systems from untrusted or external networks. For example, it enables secure remote access or plant-to-plant communication while still maintaining a hardened perimeter.

One of its standout features is Deep Packet Inspection (DPI) for industrial protocols such as EtherNet/IP, PROFINET and Modbus. Unlike basic port filtering, DPI understands what’s happening inside each packet and can enforce access rules based on specific commands or devices. This not only aligns with the access control requirements of 62443-3-3, but also provides more granular protection of critical assets.

“DPI gives you visibility and control at a much deeper level,” says Barona Andrade. “It’s a critical step for achieving SL1 or SL2 compliance — especially in environments where operational integrity is non-negotiable.”

The Anybus Defender also simplifies deployment by supporting Network Address Translation (NAT), which resolves IP conflicts and allows identical machine networks to coexist within a shared architecture. This feature is particularly useful for OEMs looking to reduce engineering hours during commissioning while keeping projects within compliance boundaries.

Another key benefit is how effectively the Defender separates OT and IT layers. With corporate networks often being the entry point for cyber threats, strict separation of control networks from general business systems is a fundamental tenet of IEC 62443. The Anybus Defender enforces this separation while still allowing the necessary data flows for analytics, cloud integration or centralised monitoring.

Importantly, the device is built with industrial reliability in mind — ready for DIN-rail mounting, harsh environmental conditions, and the kind of protocol diversity typical in modern factories. It’s also manageable via a straightforward interface, giving system designers full control without the overhead of enterprise-level cybersecurity tools.

As regulatory expectations rise, the risk of non-compliance becomes more than just technical — it can affect reputation, revenue and legal exposure. Integrators who build security in from the start are better positioned to deliver systems that not only function efficiently but also meet the needs of risk-conscious end users.

“It’s about enabling operations while protecting them,” Barona Andrade says. “The Anybus Defender gives our customers the ability to do both — with tools that match the standards they're expected to meet.”

We’re here to help

For more on how the HMS Anybus Defender can help you design secure, regulation-ready automation systems, contact NHP’s team today.

Australia: 1300 NHP NHP nhpsales@nhp.com.au

New Zealand: 0800 NHP NHP sales@nhp-nz.com

Related news & resources

Cybersecurity for Manufacturers

08/07/2025 | 500 words, 3 minutes readIn today’s connected manufacturing environment, digital transformation is reshaping how factories operate. Smart technologies are streamlining processes, improving productivity, and enabling data-driven decisions.

Safety through security

30/01/2024 | 200 words, 1 minute readAs businesses reap the benefits that greater connectivity provides for productivity and safety, there are also risks. More connection points can create more entrance points for security threats.